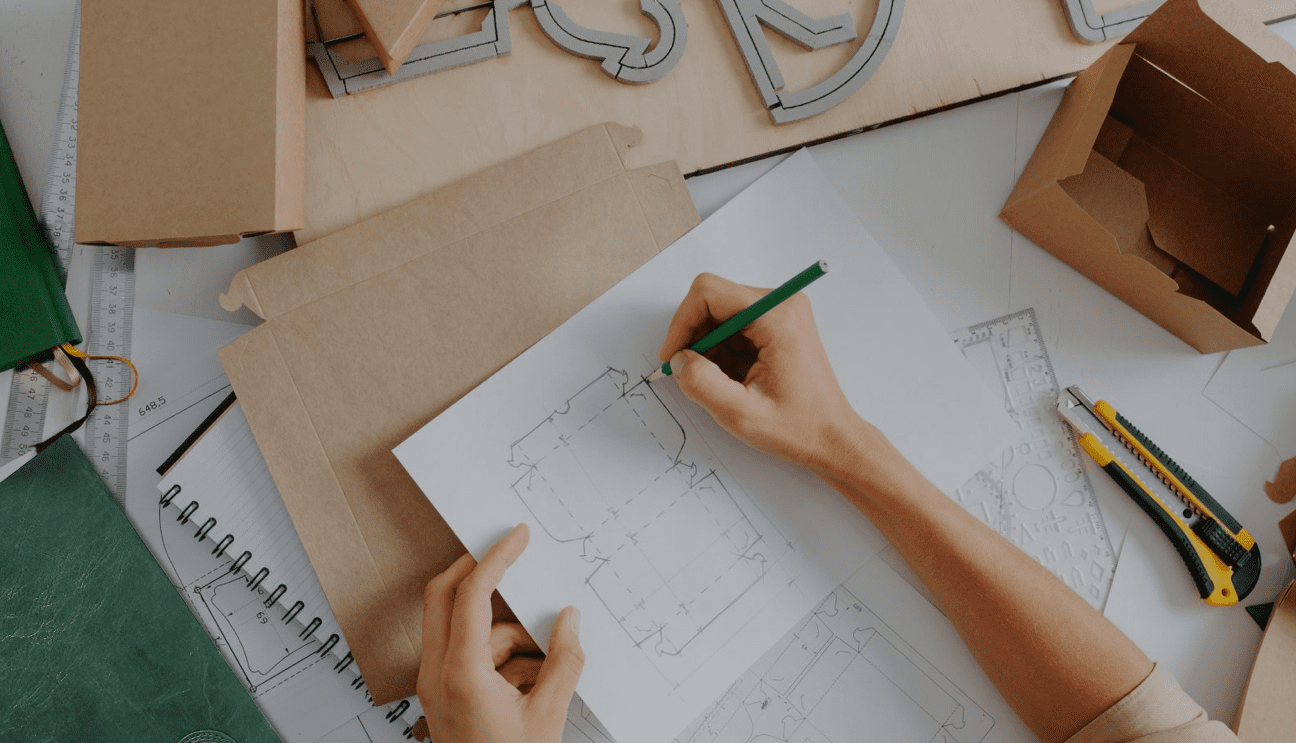

Paper packaging remains one of the most widely used and adaptable formats across industries, from consumer goods to e-commerce. Its popularity stems from its versatility, cost-effectiveness, printability, and sustainability. At the heart of great paper packaging is structural design – how paperboard is cut, folded, locked, and sealed to form a secure and visually appealing container.

This guide explores the foundational elements of paper packaging structural design. Whether you’re developing packaging for a new product, reviewing vendor samples, or optimizing for automation, understanding these core structures is essential. In turn, this knowledge supports more informed packaging decisions.

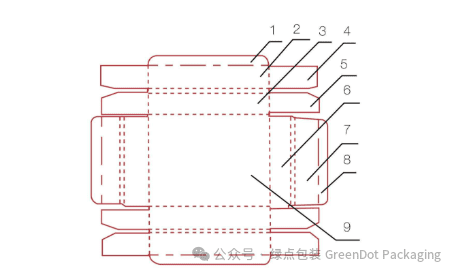

1. Cutting, Locking Tabs, and Folding

1.1 Cutting

Paperboard can be converted into a wide range of three-dimensional forms by altering the cutting pattern, commonly referred to as the dieline. Strategic cuts allow for the creation of lock tabs, folds, flaps, and display windows. Together, these elements contribute to the box’s function and visual impact.

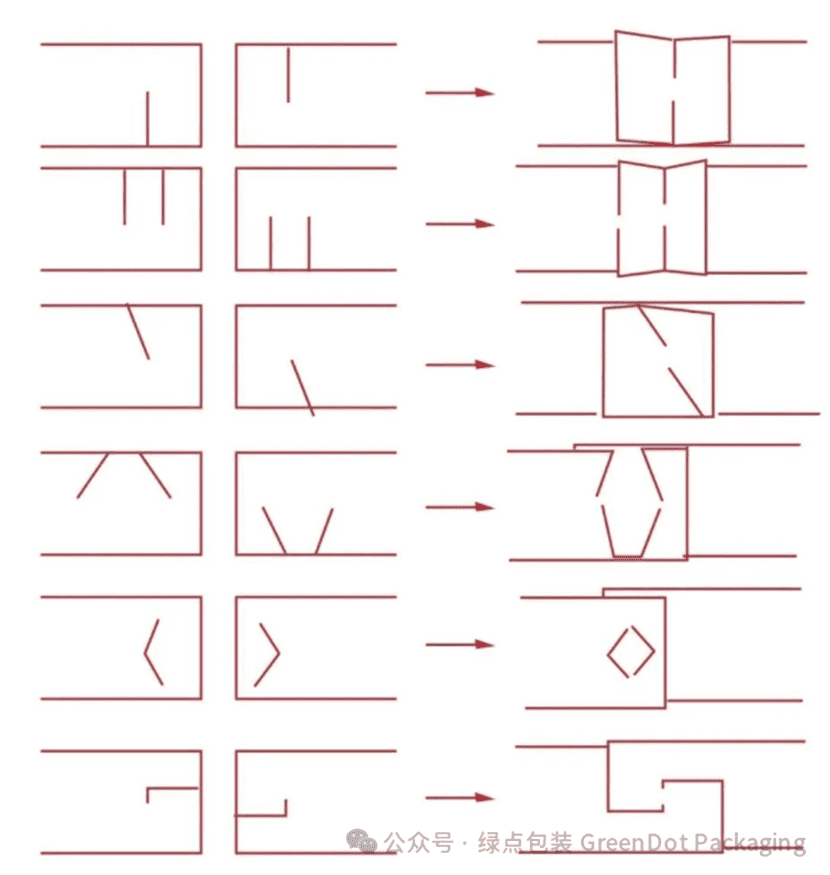

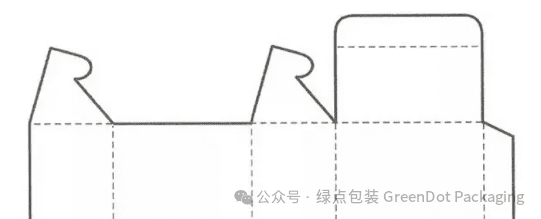

1.2 Locking / Interlocking Tabs

Locking tabs are often used when adhesives are not feasible or desired, such as in recyclable or collapsible packaging. Designers insert these tabs into precision-cut slots to create a secure closure that resists compression and pulling. Consequently, they are especially useful for retail and display-ready packaging, offering reusability and cost savings by eliminating glue.

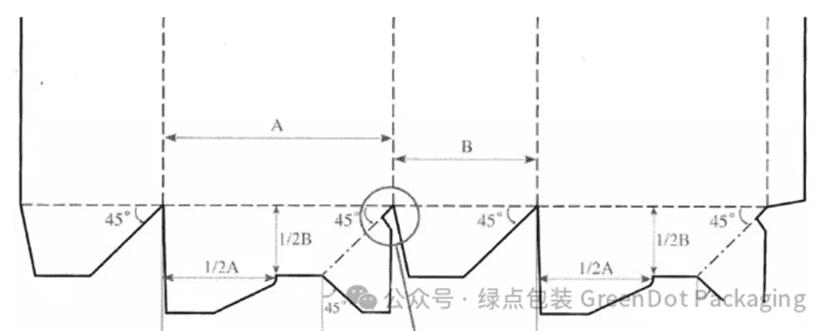

1.3 Folding

There are two primary approaches to folding paper packaging:

- Cylindrical folding: Common in rigid or curved-edge packaging, this method wraps the board along vertical crease lines.

- Die-cut and fold assembly: More typical in cartons and display boxes, this method involves cutting and scoring flat sheets, which are then folded into final shape during packing or filling.

As a result, both methods support efficient manufacturing and high-speed assembly when designed with production constraints in mind.

2. Box Lid Structures

Lid design not only determines how a box opens and closes, more importantly, it influences security, resealability, and consumer perception. To clarify the differences, below are common lid types and their performance characteristics:

2.1 Insertable Lid

This lid includes one or more locking tabs that slot into corresponding holes, providing a tamper-evident and resealable closure. Often used in household goods, toys, and pharmaceuticals, it strikes a balance between secure sealing and ease of reuse.

2.2 Insert-Lock Variant

A more secure alternative, combining tab insertion with locking notches. Ideal when added resistance to accidental opening is required.

2.3 Sticky-Seal Lid

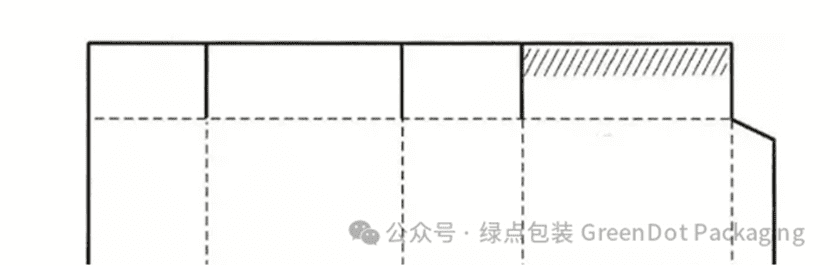

Manufacturers glue all four flaps together to create a strong, tamper-resistant seal. This design works especially well on automated production lines. As a result, it’s commonly used in food, cosmetics, and pharmaceutical packaging.

2.4 Press-Locking Closure

Uses the board’s rigidity to create a friction lock, allowing quick manual closing. Great for lightweight products and creative packaging formats.

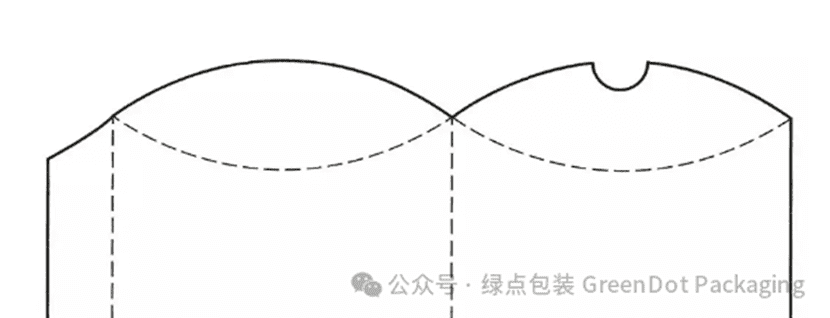

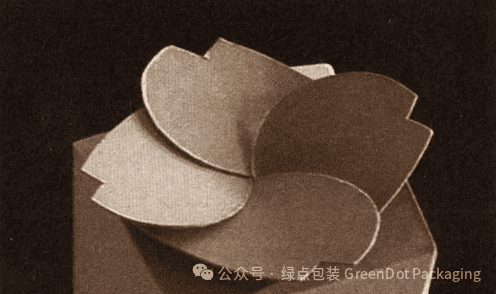

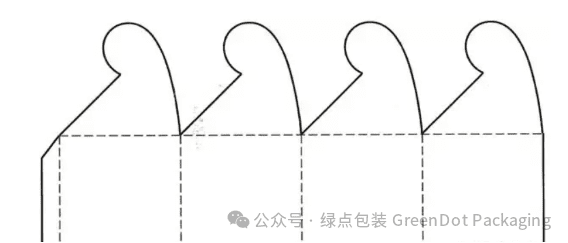

2.5 Continuous Insertion

Tabs are folded in a decorative pattern that locks the lid while enhancing shelf appeal. This structure is popular in gift packaging but typically requires manual assembly.

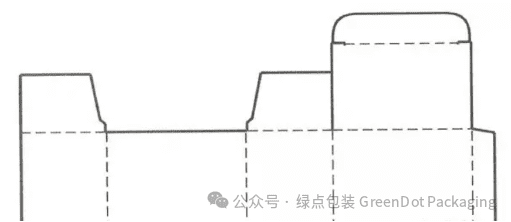

3. Bottom Closures in Paper Packaging Structural Design

The base of the package bears the product’s weight, so it must balance structural integrity with assembly efficiency. Here are the primary bottom closure designs:

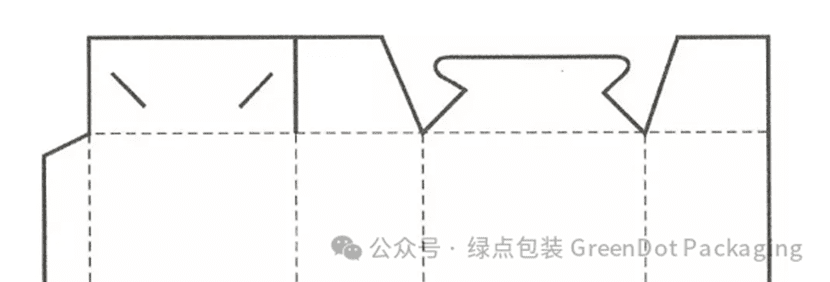

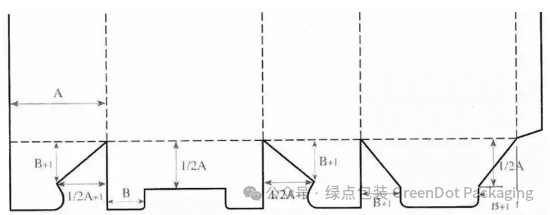

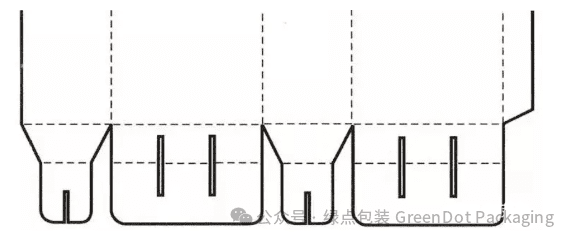

3.1 Self-Locking Bottom (Interlocking Flaps)

Four flaps interlock through a sequence of insertions and tucks. This structure is easy to assemble manually or semi-automatically. Additionally, it provides moderate weight-bearing capacity, and is widely used in retail shelf packaging.

3.2 Automatic Locking Bottom

Manufacturers pre-glue the bottom during production, allowing it to automatically lock into place when opened. It’s ideal for heavier items and high-speed production environments due to its labor-saving design.

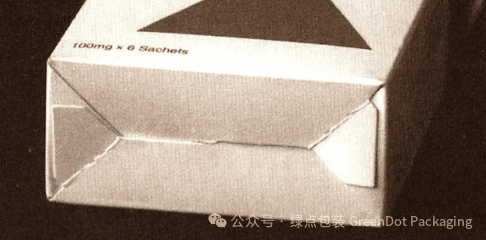

3.3 Flip-Top with Double-Wing Bottom

Packaging teams often pair this bottom closure with an insertable lid to create a simple, cost-effective design. Because of its lower load-bearing capacity, it works best for lightweight products such as toothpaste, snacks, or stationery.

3.4 Partitioned Bottom Closure

Packaging engineers design the base with integrated structural dividers to protect and organize internal components. Brands often use this format for electronics, cosmetics, and other products that include multiple parts packed together.

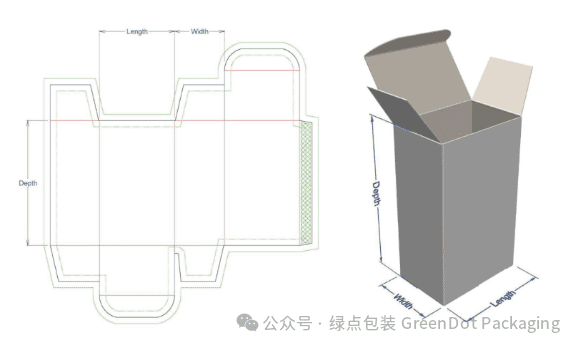

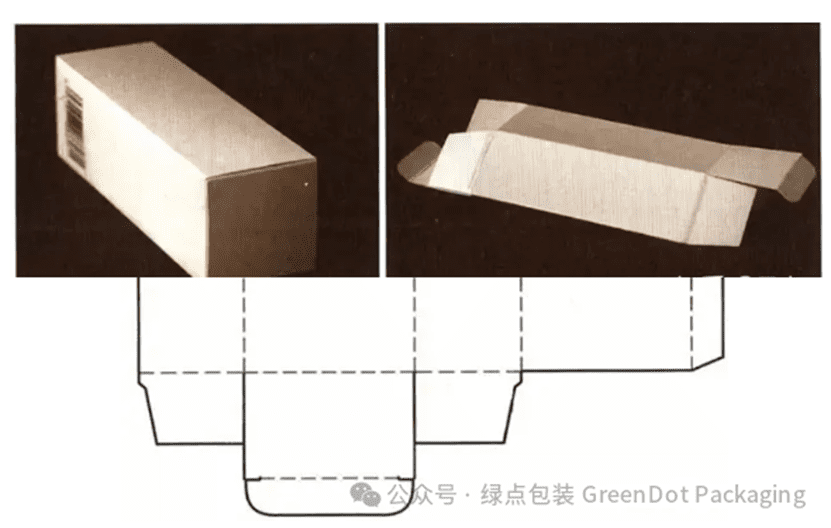

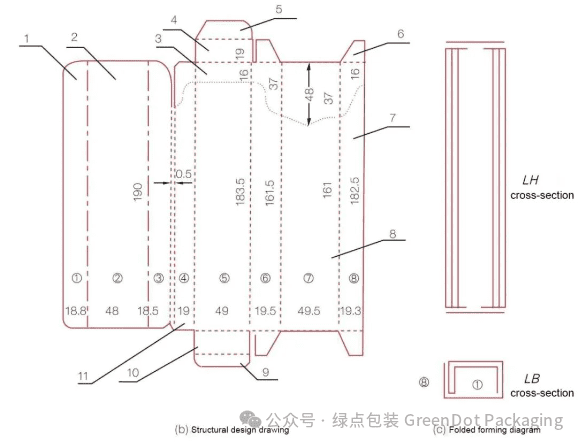

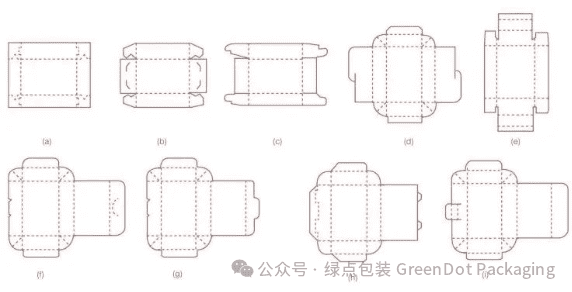

4. Tubular Folding Box

Brands commonly choose tubular folding boxes for their compact form and value them for their efficient use of material.

- Common applications: Toothpaste, films, and other narrow, elongated items.

- Key components: Panels and flaps that form the front, back, ends, and closure features. Some designs include dust flaps or inner tucks for added protection or rigidity.

- Assembly: Suppliers typically ship tubular folding boxes flat to reduce shipping volume. At the point of packing, operators fold and assemble them into shape. Designers can configure them with auto-lock bottoms or top tuck closures, depending on the product’s needs.

Tubular boxes are especially suitable for products that are consistent in shape and size and benefit from a high-volume, low-cost packaging format.

5. Tray-Style Folding Box

Manufacturers create tray-style folding boxes from a single sheet of paperboard, folding it into a tray or clamshell shape using straight or diagonal corner folds. This construction method makes them ideal for premium retail packaging where both structure and presentation are critical.

- Applications: Common use cases include apparel, gifts, confectionery, and electronics.

- Features: These boxes maintain a simple bottom structure, while most design variation happens in the lid and side walls.

- Closure methods: Depending on the needs of the product, manufacturers use glue, tuck locks, or decorative wraps to secure the box. They frequently add inner partitions or tissue to enhance presentation and product protection.

With their strong visual appeal and high level of customization, tray-style boxes give brands a powerful tool for delivering elevated unboxing experiences.

Conclusion

Mastering the structural elements of paper packaging is key to improving functionality, appearance, and production efficiency. Whether you’re sourcing packaging for a new product, optimizing existing designs, or developing packaging at scale, understanding paper packaging structural design helps you make smarter, more strategic decisions.

Need expert support with your packaging design or development? Get in touch with us to start your next project.

Need help with your packaging?

Talk to our experts about structure, testing, or branding — we’ll show you what’s possible.

- Structural design & Prototyping

- In-House ISTA Testing

- Color Consistency