Choosing the right packaging printing method is critical to aligning brand identity with cost, performance, and supply chain efficiency. Different printing techniques vary in quality, speed, substrate compatibility, and unit economics – so the right solution depends heavily on your packaging format, order volume, visual requirements, and market positioning. Whether you’re a packaging engineer optimizing production, a sourcing manager evaluating suppliers, or a brand owner balancing quality with cost, understanding these packaging printing methods helps guide effective decision-making.

1. Offset Printing (Lithography)

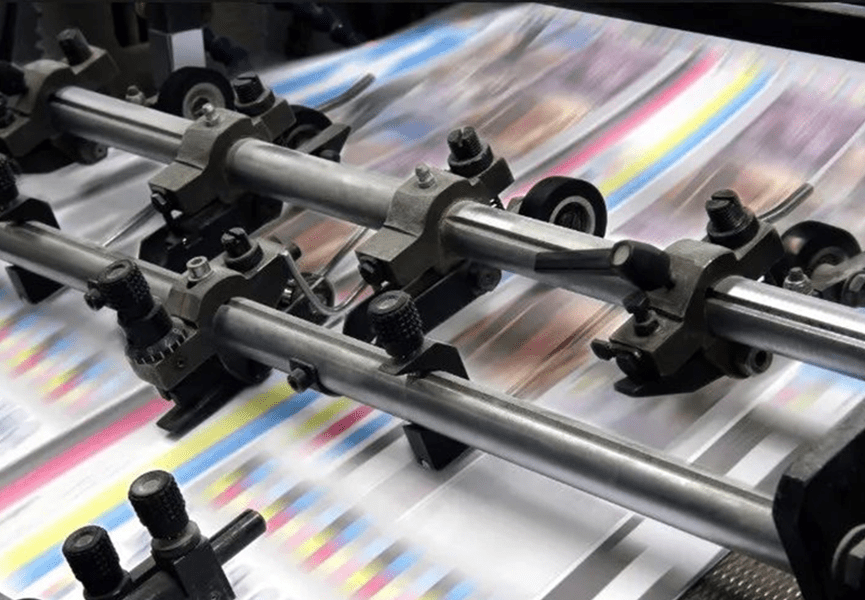

Offset printing, or lithography, is a staple in retail packaging due to its exceptional print quality, fine image resolution, and broad coating options. It is widely used for folding cartons, paperboard sleeves, rigid box wraps, and litho-labeled corrugated displays. Offset presses typically support a full CMYK process with optional spot colors and coatings, such as gloss, matte, soft-touch, UV, and aqueous finishes.

This method uses a series of etched aluminum plates and rubber blankets to transfer ink to the packaging substrate. The result is consistent, high-definition print runs – ideal for detailed graphics, gradients, and photography. Litho excels in brand-forward packaging formats where shelf appeal is paramount.

However, offset printing is best suited for medium to high-volume orders due to its substantial setup costs. Die-cutting, plate creation, and extended changeover times can be expensive for short runs or SKU proliferation. Engineers must also consider substrate constraints—offset printing is typically applied to paperboard, label stock, or linerboard wraps, rather than direct corrugated fluting or flexible films.

Best for: Premium retail packaging, color-critical applications, cartons, rigid box wraps

Not ideal for: Short-run jobs, flexible materials, variable data

2. Flexographic Printing

Flexographic printing is a high-speed rotary process favored for corrugated boxes, flexible pouches, poly bags, shrink sleeves, and paperboard cartons. It uses photopolymer plates mounted on flexible cylinders to apply ink to a wide range of substrates, including kraft, BOPP, PE, PET, and other films.

Flexo printing offers faster press speeds and lower cost per unit than litho or digital when printing at scale. It is particularly well-suited for long-run jobs where turnaround time and repeatability matter. Flexo presses can accommodate both water-based and UV-curable inks, making them versatile across applications from food-safe packaging to industrial cartons.

However, the process has limitations. Fine details, gradients, and photographic quality are harder to achieve compared to offset or digital printing. Dot gain and registration variability can impact quality. Still, for designs with limited color complexity or bold graphics, flexo offers unmatched efficiency.

Advanced flexo setups now integrate inline capabilities such as coating, cold foil stamping, die-cutting, and lamination – allowing converters to produce shelf-ready packaging in one pass.

Best for: Corrugated boxes, flexible packaging, high-volume programs

Not ideal for: High-resolution photo printing, intricate detail

3. Digital Printing

Digital printing has transformed packaging for short-run, high-SKU, and fast-turn programs. Instead of plates or cylinders, it applies ink or toner directly to the substrate via inkjet or electrophotographic technology. This eliminates setup time and tooling costs, making it ideal for prototyping, seasonal launches, promotional campaigns, and personalized packaging.

Digital printing is widely used on labels, folding cartons, corrugated boxes, and pouches, making it one of the most adaptable packaging printing methods available today. It supports variable data, QR codes, and serialized packaging – crucial for industries like food, beauty, supplements, and e-commerce.

In terms of color, digital presses use CMYK and expanded gamuts like CMYKOGV to achieve brand-consistent results. However, they generally do not support direct PMS color matching, and specialty finishes like embossing or foil require post-process steps.

Cutting is often automated via plotters or laser die-cutting, further reducing lead times and MOQs. Still, digital inks may have higher per-unit costs, making this method less efficient for long runs. Coating and durability options are also more limited compared to offset or flexo.

Best for: Short runs, fast prototyping, seasonal or regional packaging, variable data

Not ideal for: Large-volume production, exact PMS matching, luxury finishing

4. Gravure Printing

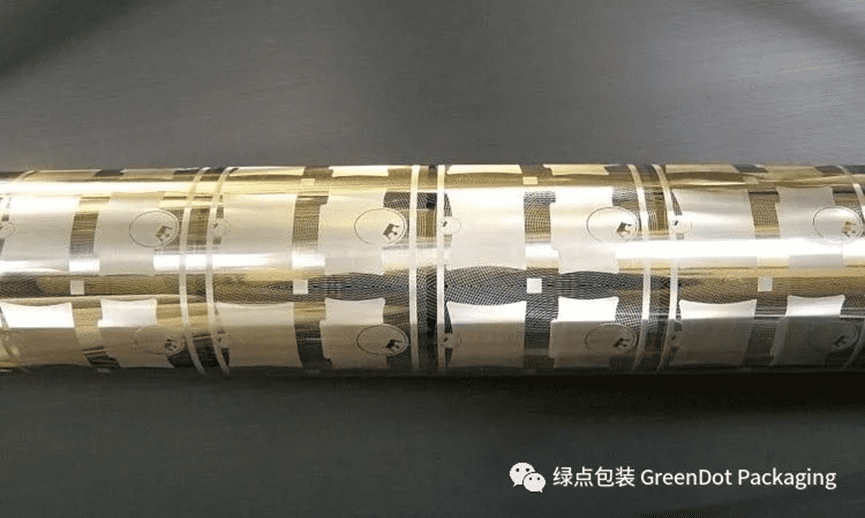

Gravure printing, or rotogravure, is a high-resolution, roll-fed method commonly used in large-scale flexible packaging. Ink is applied from engraved cylinders that create recessed cells holding varying ink volumes. This allows gravure to reproduce continuous tone imagery—photographic visuals, fine gradients, and deep color saturation.

It is particularly effective for stand-up pouches, flow wraps, and laminated films used in food, beverage, and personal care. Gravure also supports metallic inks, matte/gloss combinations, and reverse printing under laminates for durability and appearance.

The durability of gravure cylinders supports millions of impressions with consistent color quality. However, upfront tooling costs are high, and lead times for cylinder production can be long. Gravure also requires substantial ink volume to be cost-effective.

While less common for paperboard, it is still used in select high-volume folding carton projects. For sustainability-conscious brands, solvent recovery and waste ink management may be important considerations.

Best for: Ultra-high volume flexible packaging, premium photo-quality printing

Not ideal for: Low-volume orders, quick turnaround jobs, rigid substrates

5. Screen Printing

Screen printing is a versatile, manual or semi-automated process ideal for specialty applications. It uses a mesh stencil to apply ink through open areas of a screen, one color at a time. This allows it to print on substrates that are difficult for other methods—like corrugated board, rigid plastics, textiles, and uneven surfaces.

Screen printing creates bold, vibrant graphics and is often used for promotional packaging, limited-edition products, and textured surfaces. It also enables printing with specialty inks such as metallics, UV-reactive inks, and thick deposits for tactile effects.

That said, screen printing is time-intensive when handling multi-color jobs. Registration challenges and solid color limitations can reduce image fidelity. Gradients and photographic reproduction are difficult, and output tends to be slower compared to automated methods.

Still, for small production runs with unique requirements, it offers high creative flexibility and low setup costs.

Best for: Specialty packaging, tactile finishes, small promotional batches

Not ideal for: Full-color photographic designs, large-scale automation

Conclusion

Each of these packaging printing methods serves specific needs based on design complexity, substrate, print run size, and turnaround time. Offset and gravure deliver the highest quality; flexo and digital provide speed and flexibility; screen printing enables creative applications. A well-informed choice ensures not only visual impact but also operational efficiency and supply chain alignment.

For sourcing managers and product developers, selecting the right packaging printing methods starts with knowing your priorities – cost per unit, color accuracy, speed, substrate compatibility – and aligning them with your brand’s packaging goals.

Need guidance choosing the right packaging printing method for your packaging? Contact us today to speak with a packaging expert and get tailored recommendations for your next project.

Need help with your packaging?

Talk to our experts about structure, testing, or branding — we’ll show you what’s possible.

- Structural design & Prototyping

- In-House ISTA Testing

- Color Consistency