Specifying paper and paperboard correctly is foundational to packaging performance, print quality, freight cost, and retailer compliance. Yet paper weight terminology varies widely between metric and US systems, and between weight-based and thickness-based measures.

This guide explains how GSM, pounds (lbs), points (pt), and millimeters (mm) are used in US packaging and printing – and how to convert between them without costly misinterpretation.

Understanding Paper Weight vs Paper Thickness

Before converting units, it’s critical to distinguish weight from thickness. They are related, but not interchangeable.

Paper Weight (Basis Weight / Grammage)

Paper weight describes mass per unit area, not physical thickness.

- GSM (grams per square meter) is the global metric standard

- LBS (pounds) is the US customary system, based on ream weight at a defined basis size

Paper weight influences:

- Print opacity

- Tear resistance

- Mailing and freight cost

- Perceived quality

Two papers with the same GSM can have very different thickness depending on fiber type, coatings, and calendering.

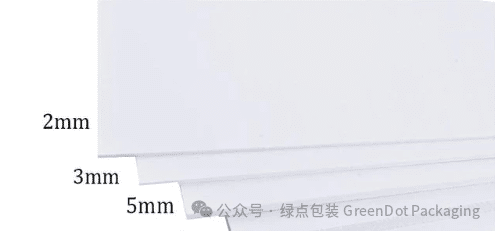

Paper Thickness

Thickness measures the actual caliper of a single sheet.

- PT (points): common in North American printing and packaging

- MM (millimeters): metric thickness measurement

Thickness primarily affects:

- Rigidity and stiffness

- Fold performance

- Die-cutting and scoring behavior

- Perceived durability

What Is GSM?

GSM (grams per square meter) measures the weight of one square meter of paper.

- Higher GSM = heavier sheet

- Often (but not always) correlates with greater thickness

- Used globally for paper, paperboard, and packaging specifications

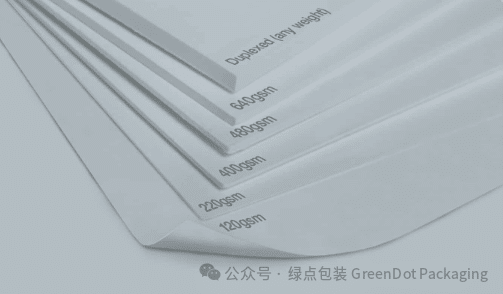

Common GSM Ranges and Typical Uses

| GSM Range | Typical Applications |

|---|---|

| 35–55 gsm | Newsprint |

| 90–100 gsm | Office / copy paper |

| 120–140 gsm | Flyers, posters |

| 210–300 gsm | Brochures, folding cartons, magazine covers |

| 350–400 gsm | Cardstock, greeting cards, rigid packaging components |

Important: Higher GSM does not automatically mean “better.” Packaging design must balance strength, machinability, cost, and logistics.

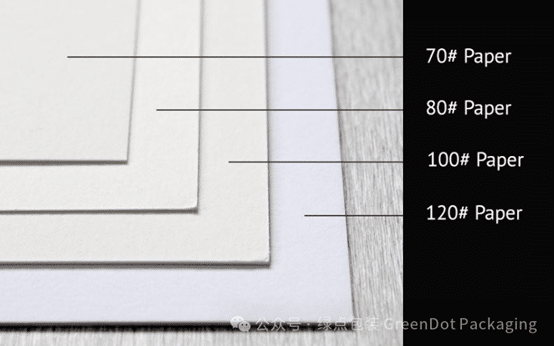

What Is LBS (Pounds)?

In the US, paper weight is often specified in pounds (lbs).

LBS refers to the weight of one ream (500 sheets) cut to a defined basis size, which varies by paper category.

Why LBS Can Be Confusing

- 80 lb text ≠ 80 lb cover

- The basis size, not the sheet you’re buying, determines the number

This is why GSM is often preferred for global sourcing and packaging engineering alignment.

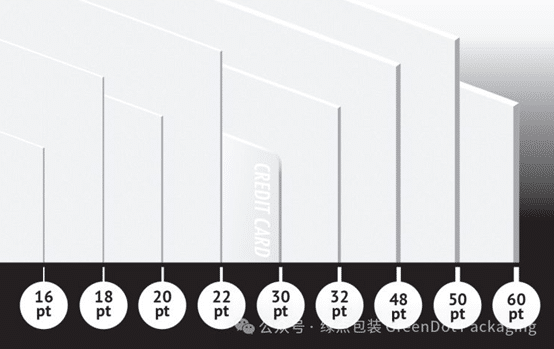

What Are PT and MM?

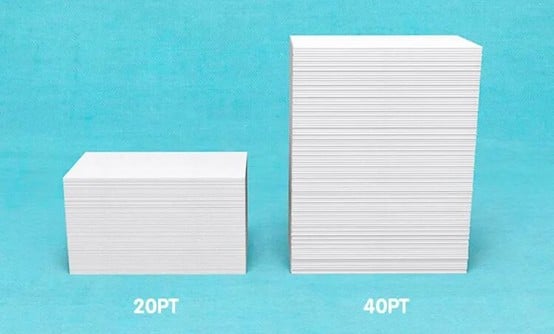

PT (Points)

- Measures thickness, not weight

- 1 pt = 0.001 inch

- Common for cardstock, labels, chipboard, and rigid packaging

Approximate industry references:

- 3–6 pt → lightweight papers

- 9–14 pt → posters, covers

- 14 pt+ → labels, tags, folding cartons

MM (Millimeters)

- Metric thickness measurement

- Often used alongside GSM for engineering clarity

Conversion:

1 pt = 0.0254 mm

Example: 14 pt ≈ 0.356 mm

Paper Weight Conversion Explained

LBS to GSM Conversion

Because pounds depend on basis size, paper weight conversion requires knowing the paper category.

| Paper Category | Basis Size | Approx. Conversion |

|---|---|---|

| Text / Book | 25″ × 38″ | GSM ≈ lbs × 1.48 |

| Cover Stock | 20″ × 26″ | GSM ≈ lbs × 2.71 |

| Bond / Writing | 17″ × 22″ | GSM ≈ lbs × 3.73 |

| Newsprint | 24″ × 36″ | GSM ≈ lbs × 1.63 |

| Index | 25.5″ × 30.5″ | GSM ≈ lbs × 1.83 |

| Bristol | 22.5″ × 28.5″ | GSM ≈ lbs × 2.20 |

These are engineering approximations. Always confirm with supplier data sheets for production specs.

PT to LBS and PT to GSM

There is no exact conversion between thickness and weight.

Why?

- Fiber density varies

- Coatings add weight without thickness

- Calendering compresses fibers

However, rough industry references are often used for early design:

| Cover Thickness | Approx. GSM |

|---|---|

| 8 pt | ~200 gsm |

| 12 pt | ~250 gsm |

| 14 pt | ~300 gsm |

| 16 pt | ~350 gsm |

| 18 pt | ~400 gsm |

These should be treated as design estimates, not purchase specifications.

Thickness Variability by Paper Type

Even at the same GSM, different papers have different calipers.

- Uncoated papers are typically thicker than coated papers

- Recycled fibers may increase bulk

- High-gloss coatings increase weight more than thickness

Always rely on:

- Supplier caliper data

- Material technical datasheets

- Physical samples for validation

Get Paper Specifications Right the First Time

Paper weight and thickness confusion is one of the most common sources of print failures, cost overruns, and packaging performance issues. Understanding how GSM, lbs, pt, and mm relate, and where they don’t convert cleanly, helps teams avoid mis-specification before it reaches production, testing, or retail review.

Because paper density, coatings, and manufacturing methods vary widely, conversion charts should guide design – not replace supplier validation and engineering review. For packaging applications, weight and thickness must always be evaluated in the context of structural performance, print process, logistics, and retailer requirements.

Contact GreenDot today to review paperboard specifications, help with paper weight conversion, validate material choices, or align your packaging designs with real-world manufacturing and retail expectations — before issues surface downstream.

Need help with your packaging?

Talk to our experts about structure, testing, or branding — we’ll show you what’s possible.

- Structural design & Prototyping

- In-House ISTA Testing

- Color Consistency