Meeting Sam’s Club’s packaging requirements isn’t just about getting your product to market — it’s about protecting the member experience, optimizing the supply chain, and ensuring every shipment meets performance expectations from dock to display.

Sam’s Club has some of the most precise packaging protocols in the club retail industry, emphasizing sustainability, efficiency, and structural strength.

This guide summarizes the official Sam’s Club Direct Import Packaging Requirements and provides engineering insights and actionable steps to help suppliers build packaging that’s both compliant and cost-effective.

Every Sam’s Club item — from large appliances to private-label goods — must pass a series of internal reviews before approval. According to Sam’s Club Packaging Requirements, products that fail can lead to:

Shipping or display rejections at distribution centers

Costly repackaging or retesting delays

Risk of lost shelf space for new items

Each new or modified product must complete the Packaging Intake Sheet and receive formal packaging approval from Sam’s Club’s packaging team. Compliance is confirmed only after:

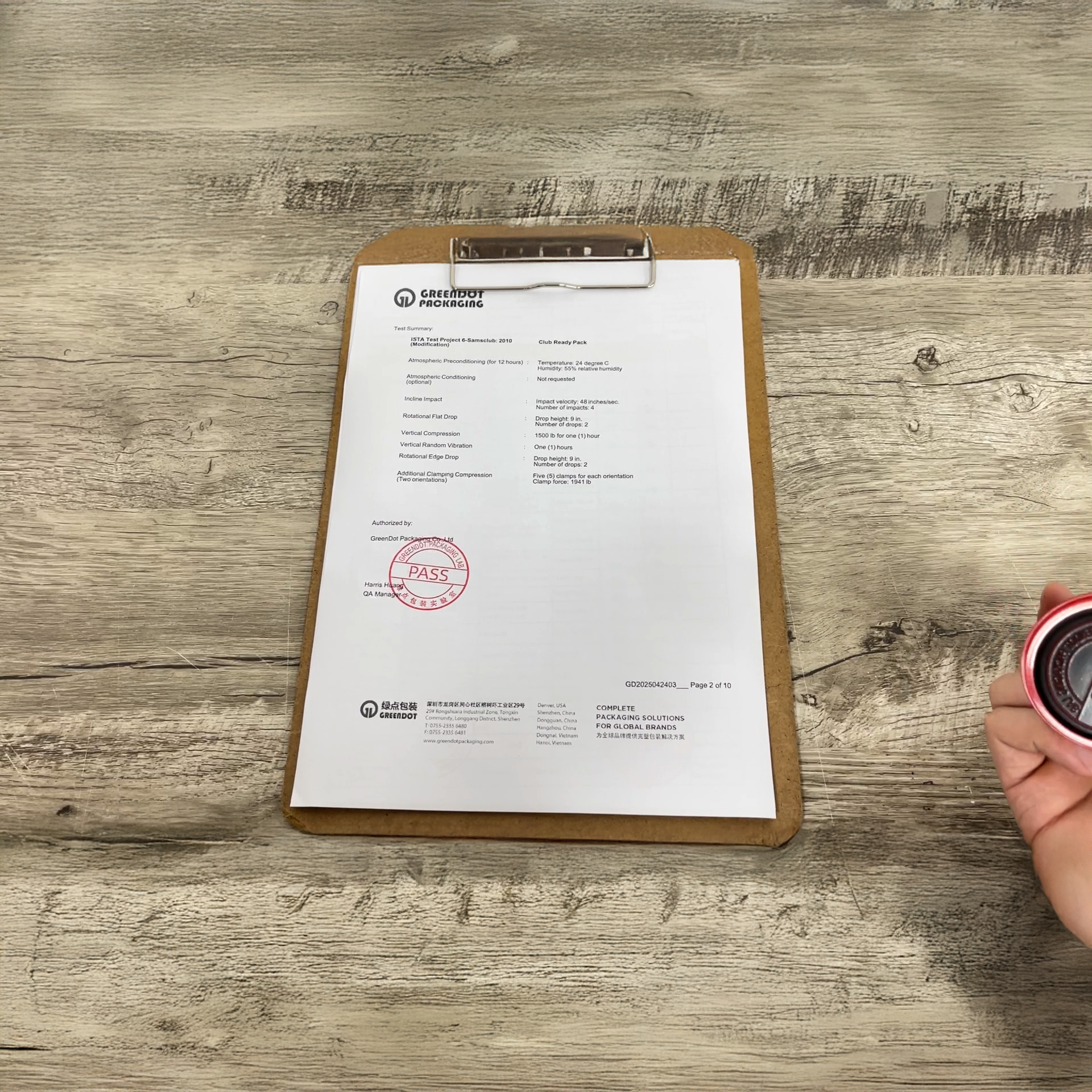

ISTA-6 testing (Sam’s Club or FedEx-modified protocol)

BV inspection (stacking and drop testing)

Review of sustainability and labeling standards

Core standards every supplier must meet — from club-ready pallet design to sustainability, testing, and labeling compliance.

Sam’s Club prefers “Club Ready Packs” — pallets that can go directly onto the floor with no assembly

Products should be 3–4 sides shoppable and require no cutting or setup in-club

Maximum height: 48″ (excluding pallet)

Pallet base: 40″ × 48″ standard; no overhang, ≤3″ underhang

Use easy-to-remove wrap and ensure clean presentation when unwrapped

Maximum pallet weight: 2,500 lbs including pallet

Follow approved pallet rendering and pattern from the Sam's Club Packaging Requirements Packaging Intake Sheet

No double-stacking unless specifically tested for compression strength

All pallets must fit within Sam’s IDC clamp and forklift handling parameters

ISTA-6 Sam’s Club Test required for all in-club and Mexico orders

Modified ISTA-6 FedEx Test required for Dotcom and DSV shipments

Additional testing:

7-Day Stacking Test (1,500–2,500 lbs)

Drop Test for floor-loaded cartons

Sutherland Rub Test (ASTM D5264) for printed packaging durability

Packaging must stay within ±5% variance for weight and CBM vs. the approved quote sheet

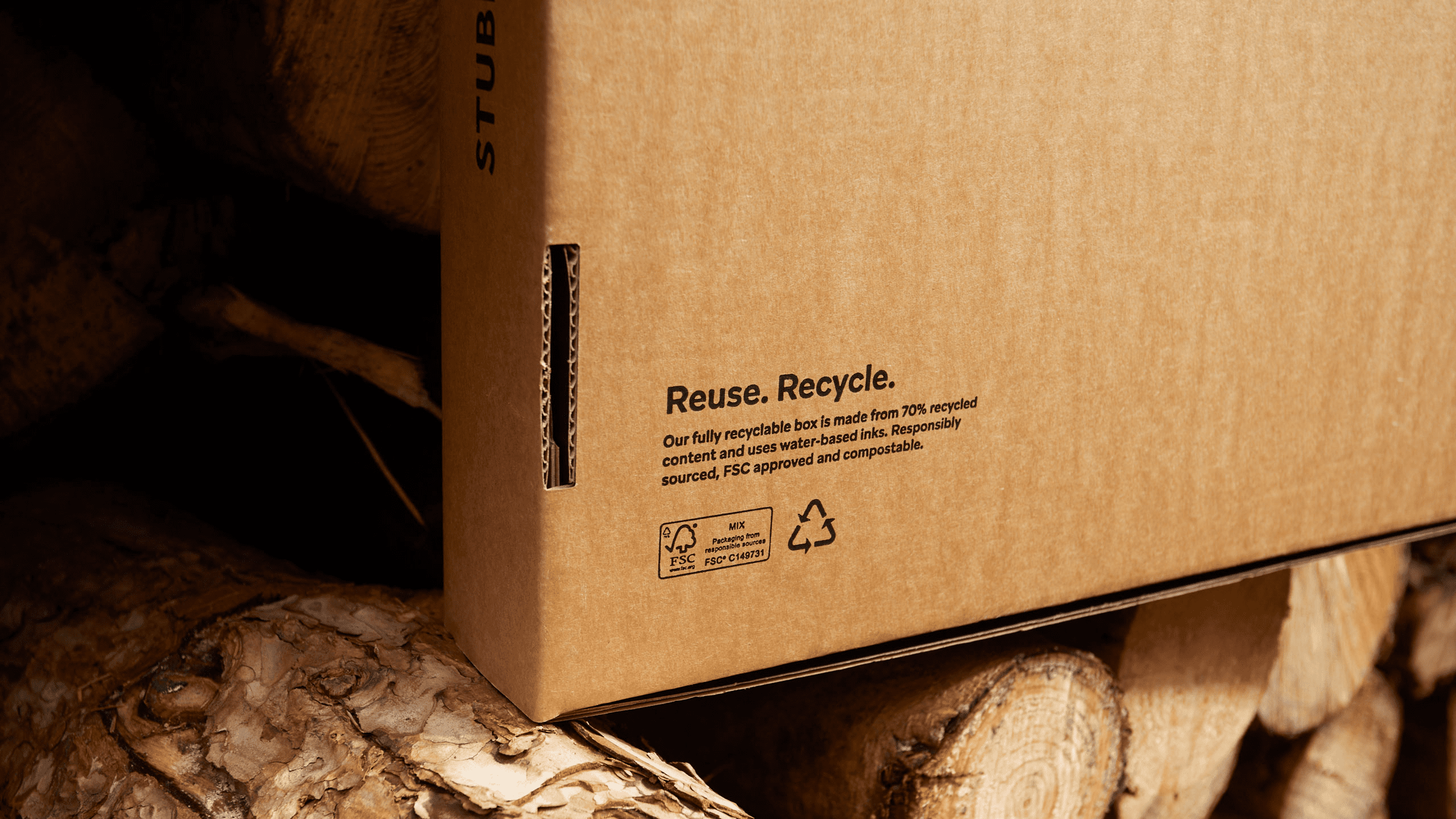

Goal: 100% recyclable, reusable, or compostable packaging by 2025

Join the How2Recycle® program (code “Walmart”) for all private-brand items

Use water-based inks and eliminate poly coatings or UV finishes

Flexible materials must be PE-based films (LDPE/LLDPE/HDPE) with ≥20% PCR when possible

Replace foam inserts with fiber-based or molded pulp components

Every selling unit must have a UPC-A (GTIN-12) or EAN-13 (GTIN-13) barcode

Scan grade: B or higher; color: black on white background

Barcode size: 1.5″ × 0.75″ to 3″ × 2″

Shipping marks printed on two adjacent sides with item #, PO #, COO, and “TO: US"

Gross weight > 500 lbs must be printed in red

All corrugated packaging must display a Box Manufacturer’s Certificate (BMC)

Minimum board strength: 32 ECT (200 B Mullen) for primary cartons; 44–48 ECT for trays and shrouds

Printed surfaces must pass the Sutherland Rub Test for ink adhesion

Use water-based coatings and avoid plastic-laminated papers or films

Keep paper/MDF moisture below 14% before loading

Inspect containers for rust, damage, or leaks before loading

Use approved desiccant vendors (Super Dry®, Micro-Pak®)

For gap spacing and load stability, add airbags and netting as specified in the guide

Sam’s Club’s global supply chain involves multiple handling methods – including forklifts, clamp trucks, and slip-sheet handling – across import distribution centers (IDCs), domestic DCs, and in-club receiving areas.

According to Sam’s Club Packaging Requirements, packaging must remain stable and intact through:

Clamp handling: Pallets and cartons are frequently moved with clamp trucks; outer packaging must resist lateral compression and edge deformation.

Fork and slip-sheet handling: All pallet designs must accommodate 48″ × 40″ pallets and allow entry from all sides.

Cross-docking and mixed loads: Products are often combined with other SKUs and double-stacked during transfer. Packaging must protect contents even when heavier items are stacked above.

Sam’s Club packaging requirements specifically notes that display and shipping packs should survive clamp pressure without tearing, crushing, or shifting, ensuring member-ready presentation upon arrival.

During warehouse and in-club storage, Sam’s pallets may be double-stacked or stored long-term. To verify stacking strength:

7-Day Stacking Test is required for all club-ready and floor-loaded items.

Test load: 1,500–2,500 lbs applied continuously for 7 days.

Include a 48″ × 40″ × 5.5″ pallet on both the top and bottom of the test unit.

Box strength verification: The master carton must withstand compression for the full duration without collapse or visible deflection.

On-site verification: Bureau Veritas (BV) inspectors review stacking-test data during final inspection of first shipments.

Only packages that maintain structural integrity and dimensional stability throughout the test window are cleared for shipment, according to Sam’s Club packaging requirements.

All new or modified packaging must complete Sam’s Club’s transit test program prior to approval.

In-Club and Mexico orders: Follow ISTA-6 Sam’s Club test protocol.

Omni / Dotcom Orders: Follow Sam’s Modified ISTA-6 FedEx protocol.

High-risk or non-standard packs: May require additional or modified testing, including vibration, drop, and clamp trials.

Marginal Pass tolerance: ± 5 % difference in cube (CBM) or gross weight between test sample and quoted sheet is accepted; beyond that requires corrective action.

ISTA results, along with the approved Intake Sheet, must be shared with Sam’s Packaging before any production shipment is authorized.

Sam’s logistics network spans diverse climates and long ocean transit times. To meet Sam’s Club packaging requirements, packaging materials must therefore resist moisture, temperature swings, and compression fatigue.

Environmental requirements include:

Maintain paperboard and corrugated moisture content ≤ 14 % before packing.

Inspect containers for rust, leaks, or wet floors prior to loading.

Use desiccant bags sized for seasonal humidity (approved suppliers: Super Dry®, Micro-Pak®).

Employ airbags or nets to stabilize gaps larger than 4–6 inches in containers.

Ensure all corrugated components display a Box Manufacturer’s Certificate (BMC) with tested Mullen / ECT values.

These measures prevent “container rain,” mold formation, and load shifting during transit — protecting both product and presentation quality at club level.

Sustainability is central to Sam’s Club’s packaging strategy. Suppliers are expected to design for recyclability and material reduction without compromising durability.

Sustainable choices are reviewed as part of the official packaging approval and can affect acceptance of Member’s Mark or private-brand products.

Before the first shipment of any new item:

The factory must provide a completed Container Loading Inspection Report with images showing pallet pattern, loading order, and securing methods.

BV inspectors verify compliance with approved diagrams, carton orientation, shipping marks, and container utilization (≥ 90 %).

Only packages that pass all mechanical, labeling, and sustainability checks receive final Sam’s Club packaging approval.

Designing for Sam’s Club packaging requirements means engineering packaging that performs through long-distance freight, clamp handling, high stacking pressure, and strict sustainability benchmarks.

By validating structure, moisture control, labeling, and load efficiency upfront, suppliers can ensure smooth approvals and consistent on-floor presentation across Sam’s Club’s global network.