If you’ve ever noticed a circle-shaped seal printed on the bottom of a corrugated box, you may have wondered what it represents. That circular stamp is called a Box Maker’s Certificate (BMC) mark. While it may look simple, the BMC mark provides valuable information about the carton’s strength, structure, and compliance with industry standards.

In this article, we’ll explain what the BMC is, why it matters, and how it relates to carton testing methods such as Edge Crush Test (ECT) and Burst Strength Test. We’ll also break down carton wall classifications and what brand managers and sourcing professionals should look for when evaluating packaging.

What is a Box Maker’s Certificate (BMC)?

The Box Maker’s Certificate is essentially a quality assurance seal printed on corrugated cartons. It confirms that the carton manufacturer has tested the box and that it meets the stated strength ratings.

While not legally required, the BMC provides assurance to retailers, logistics companies, and end customers that the packaging has been manufactured to a specific standard. The BMC mark also allows brands to compare packaging across suppliers more easily.

Key points the Box Maker’s Certificate communicates:

- Type of board construction (single wall, double wall, or triple wall)

- Test method used (Bursting Test or Edge Crush Test)

- Maximum size and weight limits the carton is certified to handle

- The manufacturer’s identity and location

For packaging buyers, this mark provides confidence that the packaging aligns with shipping, handling, and retail compliance standards.

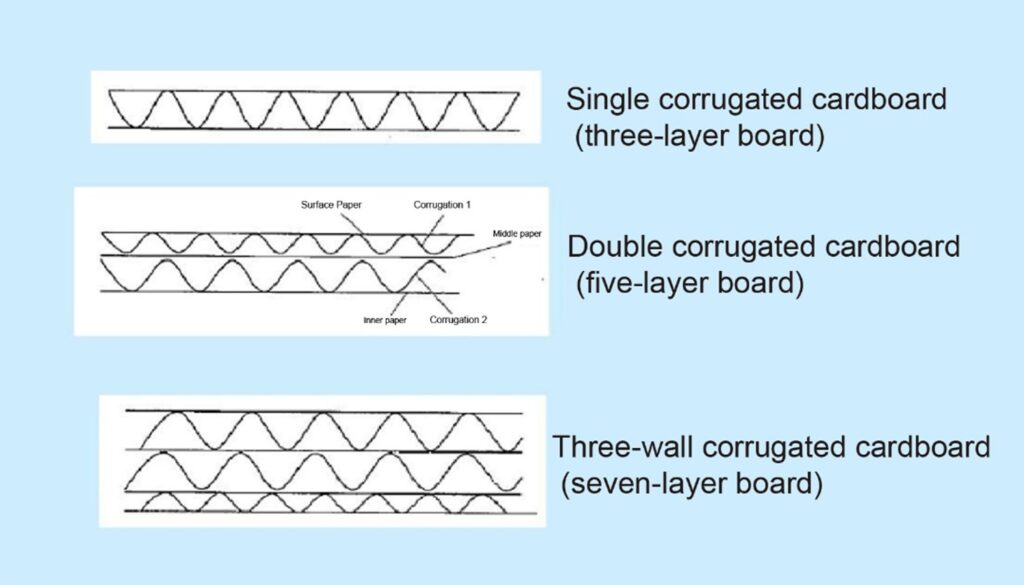

Corrugated Box Wall Classifications

Before understanding the test methods on the BMC, it’s helpful to review corrugated box structures. Corrugated board is made of layers of linerboard (flat sheets) and medium (fluted paper).

- Single Wall (3-ply):

- Consists of an outer liner, fluted medium, and inner liner

- Most common type of corrugated board

- Suitable for lightweight products and eCommerce packaging

- Double Wall (5-ply):

- Two layers of fluting sandwiched between three liners

- Provides greater strength for heavier goods or items requiring more protection

- Often used in shipping cartons for retail or industrial supply chains

- Triple Wall (7-ply):

- Three layers of fluting and four liners

- Extremely durable, comparable to wooden crates in strength

- Used for bulk shipments, export packaging, or very heavy products

The Box Maker’s Certificate mark will indicate which type of board is used so that buyers and logistics teams know the expected performance range.

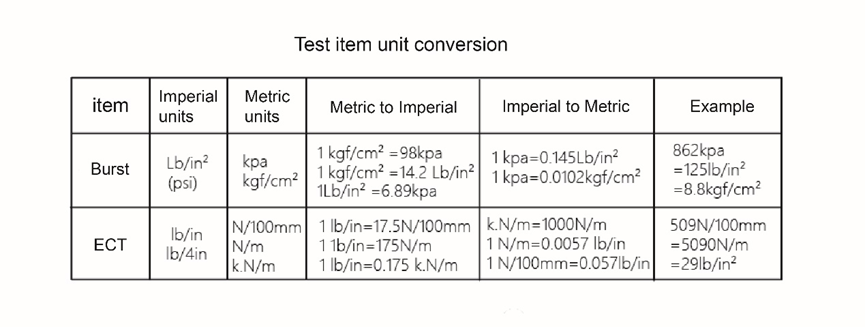

Edge Crush Test (ECT)

One of the most common values you’ll see on a BMC is the Edge Crush Test (ECT) rating.

The ECT measures how much pressure a corrugated board can withstand on its edge before collapsing. It reflects the box’s ability to resist crushing under stacking loads, making it a critical measure for warehousing and palletized shipments.

How it’s tested:

- A strip of corrugated board is placed vertically in a compression tester

- Pressure is applied until the board buckles

- The result is expressed in pounds per inch (e.g., 32 ECT)

What it means in practice:

- 32 ECT single wall board is common for eCommerce boxes and lightweight retail packaging

- 44 ECT or higher may be specified for larger boxes, heavier contents, or tougher shipping environments

- Retailers often mandate a minimum ECT value to ensure packages survive supply chain handling

For many brands, ECT is the preferred measure because it more directly represents stacking strength, which is critical in distribution centers.

Bursting Strength Test (Mullen Test)

Another method found on some Box Maker’s Certificate marks is the Bursting Strength Test, also known as the Mullen Test.

This test measures the force required to rupture the corrugated board using a rubber diaphragm that exerts pressure until the board bursts.

How it’s tested:

- A hydraulic system applies pressure through a flexible membrane onto a circular area of board

- The result is expressed in pounds per square inch (e.g., 200# burst)

What it means in practice:

- Burst strength is more relevant for measuring resistance to puncture or rough handling

- Common values include 200#, 275#, or higher, depending on carton strength

- Historically, many industries (such as food or consumer goods) relied on burst strength as the standard measure

Today, however, most U.S. retailers and distribution centers prefer ECT ratings, as they better correlate with pallet stacking performance.

ECT vs. Burst: Which is Right for You?

Choosing between ECT and Bursting Strength depends on the application:

- ECT is preferred for shipping cartons stacked on pallets, warehouse storage, and distribution environments.

- Burst Strength is preferred when puncture resistance and durability against rough handling are more critical.

Many retailers specify which test method they accept in their packaging compliance guidelines. Failing to meet these requirements can result in rejected shipments, added costs, or delays.

Why the BMC Matters for Brands and Retailers

For packaging professionals, the Box Maker’s Certificate mark provides more than just technical data—it’s a signal of compliance, quality, and consistency.

- Compliance: Retailers often require proof of carton strength. The Box Maker’s Certificate makes it easy to confirm.

- Cost Optimization: By matching box strength to product weight and shipping method, brands can avoid over-packaging while still meeting standards.

- Sustainability: Using the right BMC-certified carton can help reduce unnecessary fiber usage, supporting sustainability goals without compromising strength.

- Risk Reduction: Ensures cartons won’t fail in transit, reducing damage claims and improving customer satisfaction.

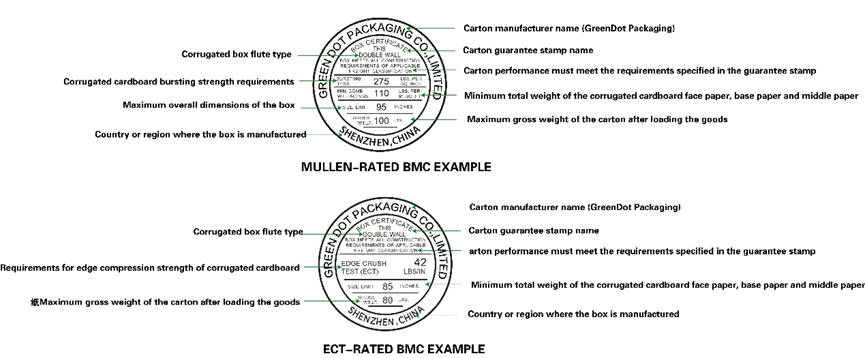

How to Read a BMC Mark

While the design of the seal can vary, a typical Box Maker’s Certificate mark includes:

- The board type (single, double, or triple wall)

- The test method (ECT or Mullen burst)

- The certified strength value (e.g., 32 ECT or 200# burst)

- Maximum size limit and gross weight certification

- Manufacturer’s name and location

Conclusion

The Box Maker’s Certificate (BMC) mark is a small but critical detail in corrugated packaging. By understanding what it represents, brand managers and sourcing professionals can make smarter decisions about packaging strength, compliance, and cost efficiency.

Whether you’re shipping lightweight eCommerce products or heavy industrial goods, the Box Maker’s Certificate ensures your cartons are tested and rated for the job.

Ready to Optimize Your Packaging?

Understanding Box Maker’s Certificate (BMC) marks is only the first step. The right carton strength and certification can mean the difference between smooth delivery and costly product damage.

GreenDot Packaging works with leading brands to design, test, and deliver packaging that passes compliance checks, reduces cost, and meets sustainability goals.

Contact us today to discuss your packaging needs and see how we can help you achieve packaging that’s stronger, smarter, and fully retailer-compliant.

Need help with your packaging?

Talk to our experts about structure, testing, or branding — we’ll show you what’s possible.

- Structural design & Prototyping

- In-House ISTA Testing

- Color Consistency