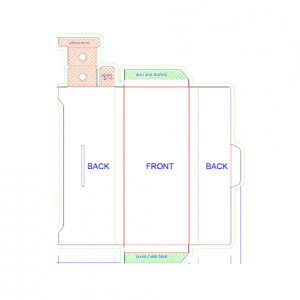

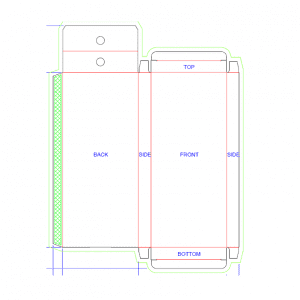

At GreenDot Packaging, structural engineering is the foundation of our packaging success. We don’t just design boxes – we engineer solutions that meet rigorous performance, cost, and retail display requirements.

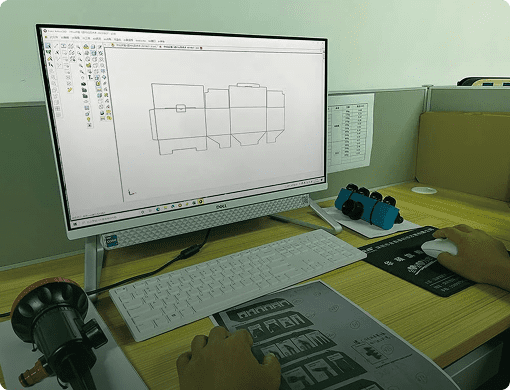

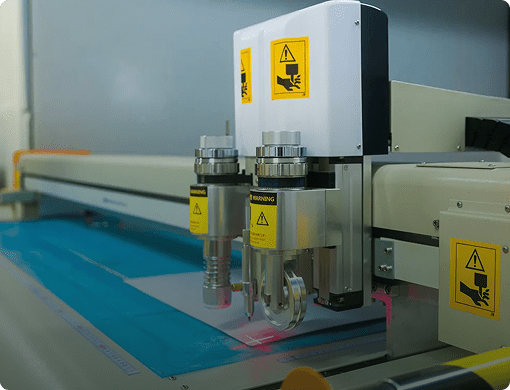

Our structural design team partners with you from the initial concept stage through to the delivery of fully assembled white or printed prototypes. We use CAD tools and cutting tables to iterate dielines quickly, allowing for fast feedback and refinement cycles.

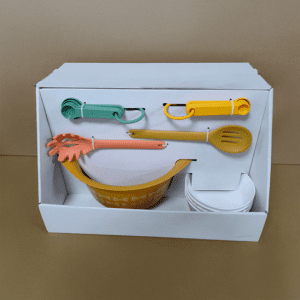

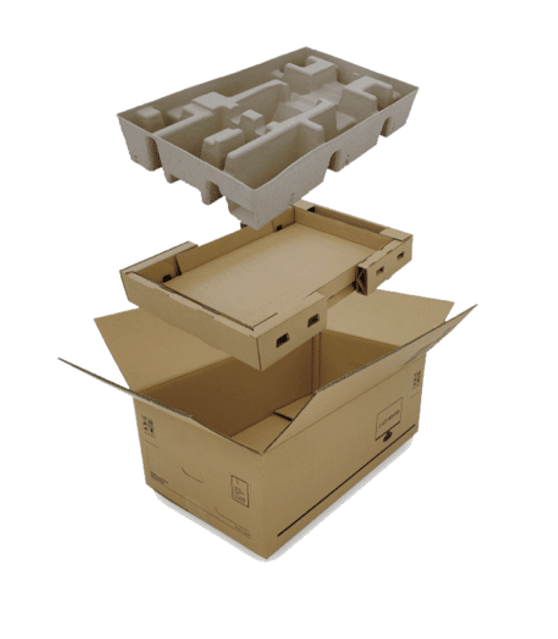

We engineer packaging to fit product dimensions precisely, minimize material waste, and ensure compatibility with both hand-assembly and automated fulfillment systems. Whether you’re shipping fragile items or retail displays with high weight loads, we account for:

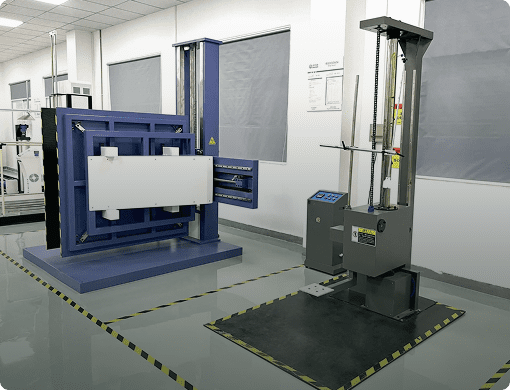

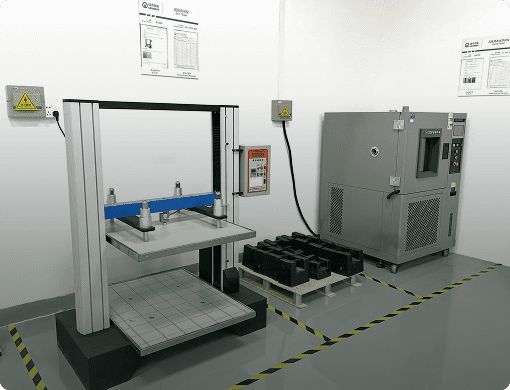

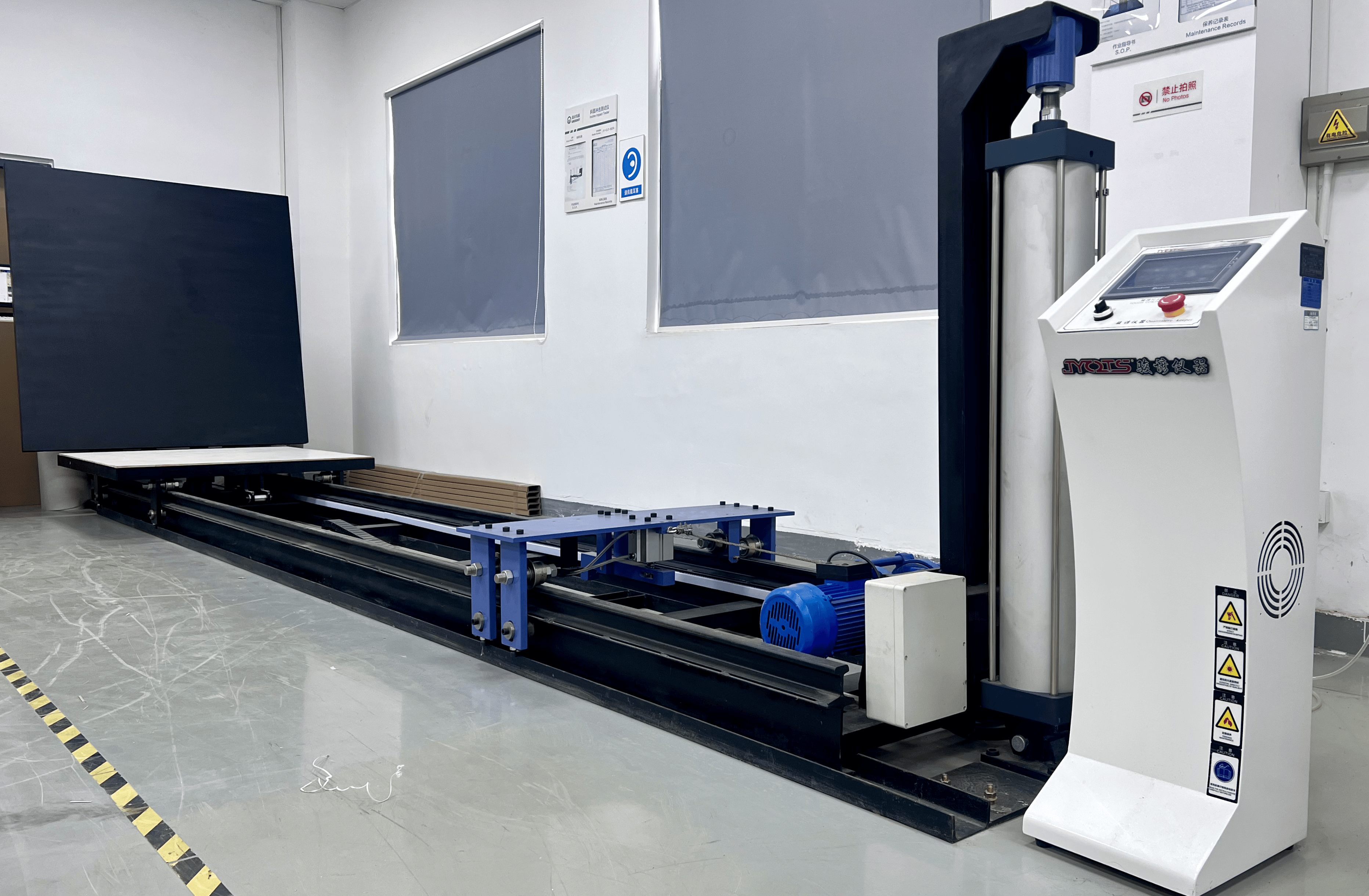

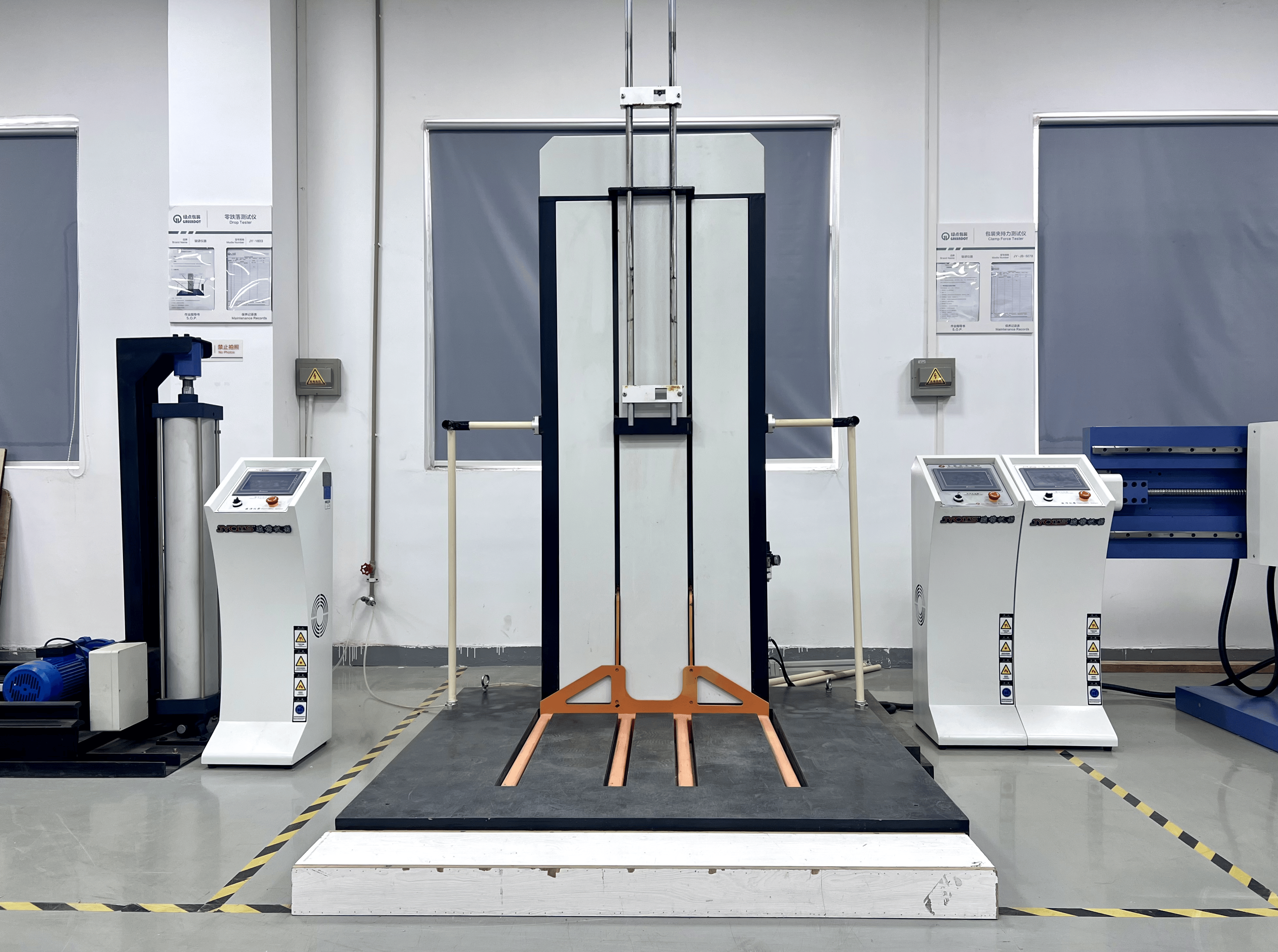

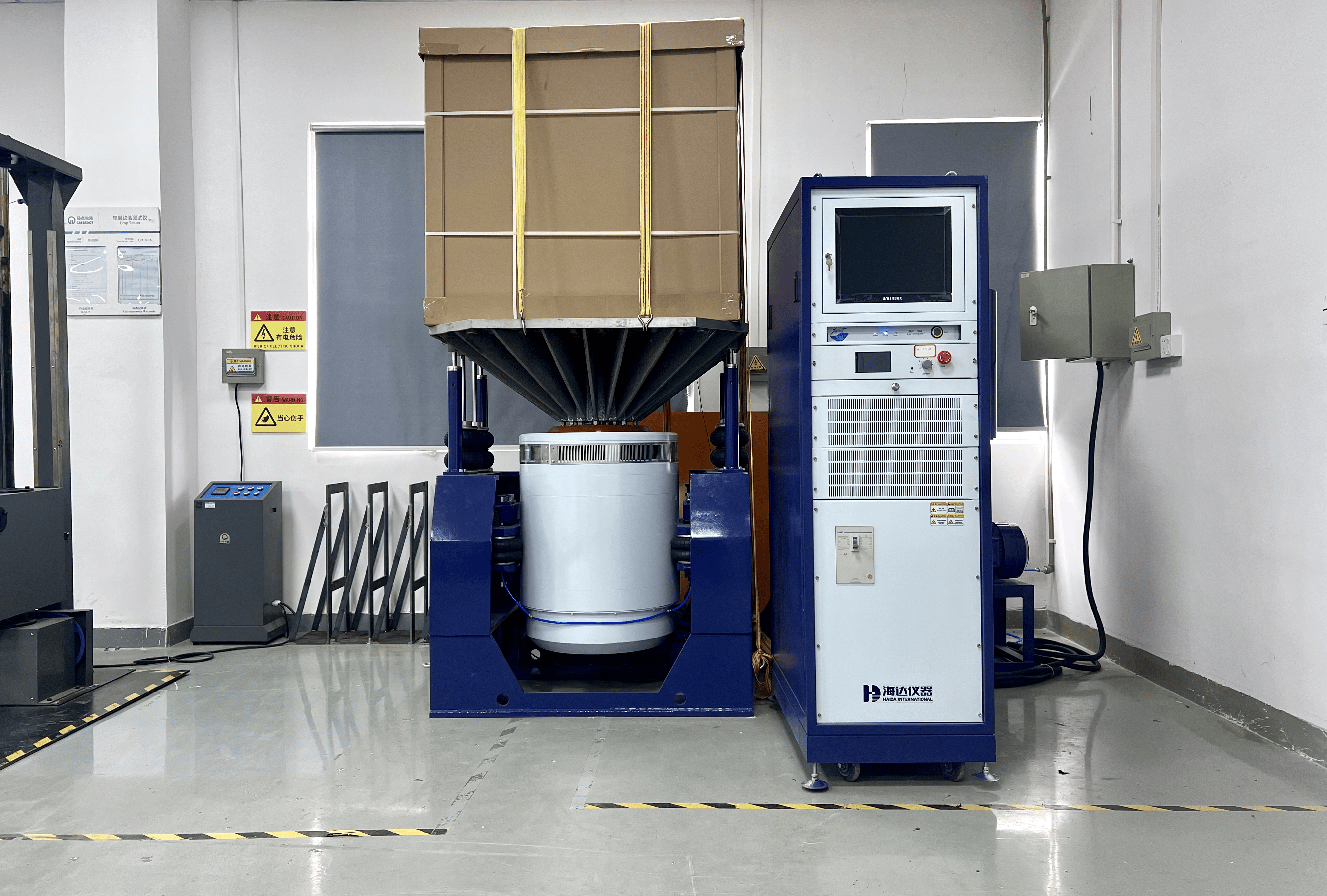

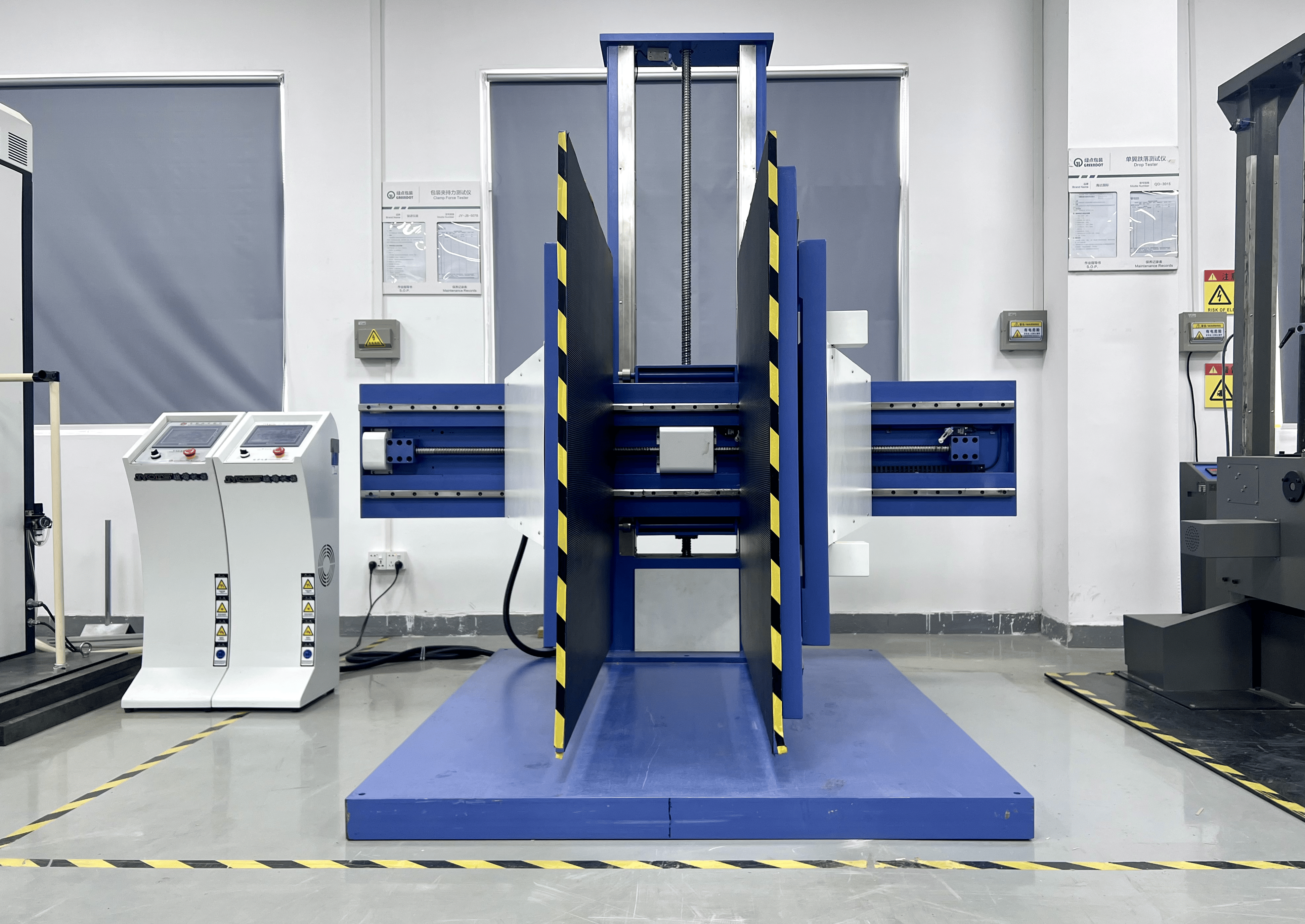

Every design is validated using ISTA-certified in-house testing. That means we don’t guess - we prove structural performance through drop tests, vibration simulations, and crush resistance assessments, reducing your risk of failure during transit or retail handling.

We engineer packaging that aligns with major retailer requirements, including Sam’s Club, Walmart, and Costco. That means:

Correct overhang clearance

Efficient pallet pattern optimization

Shelf- and endcap-compatible designs

Floor-ready display integration

Container cube optimization for cost-effective shipping

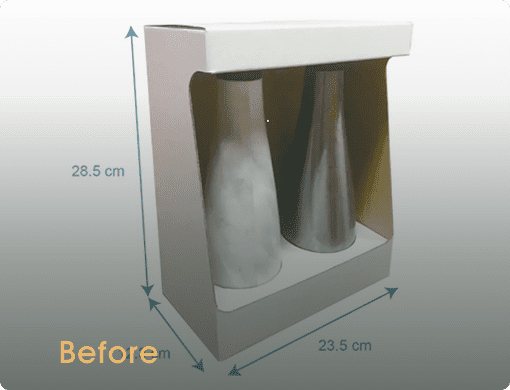

A recent client struggled with rising freight costs due to oversized packaging. We redesigned the structure to reduce box volume by 18% while maintaining protection levels - resulting in a 12% reduction in freight costs and improved shelf presence.

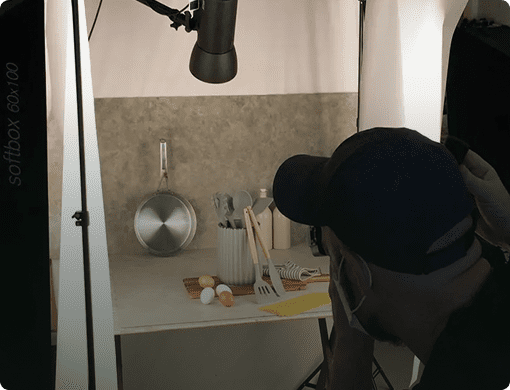

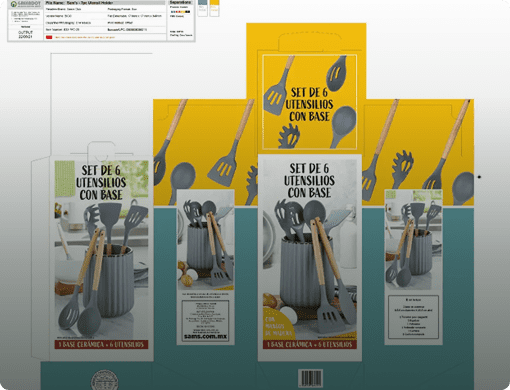

From carefully staged product photography to retail-ready artwork and polished mockup renderings, our creative process transforms your product into packaging that commands attention. We handle every step – shooting, editing, layout, and visualization – with precision and an eye for brand impact.

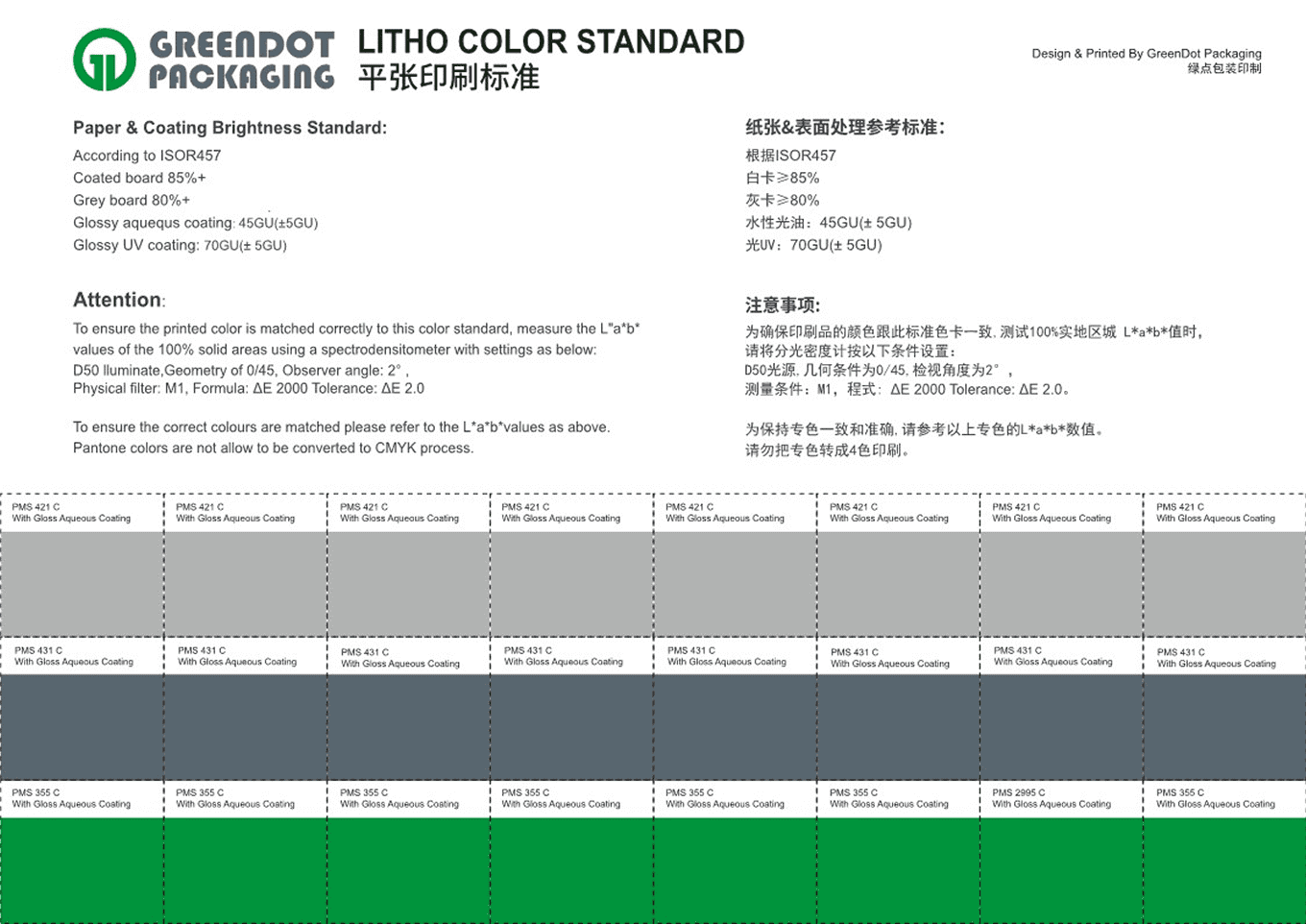

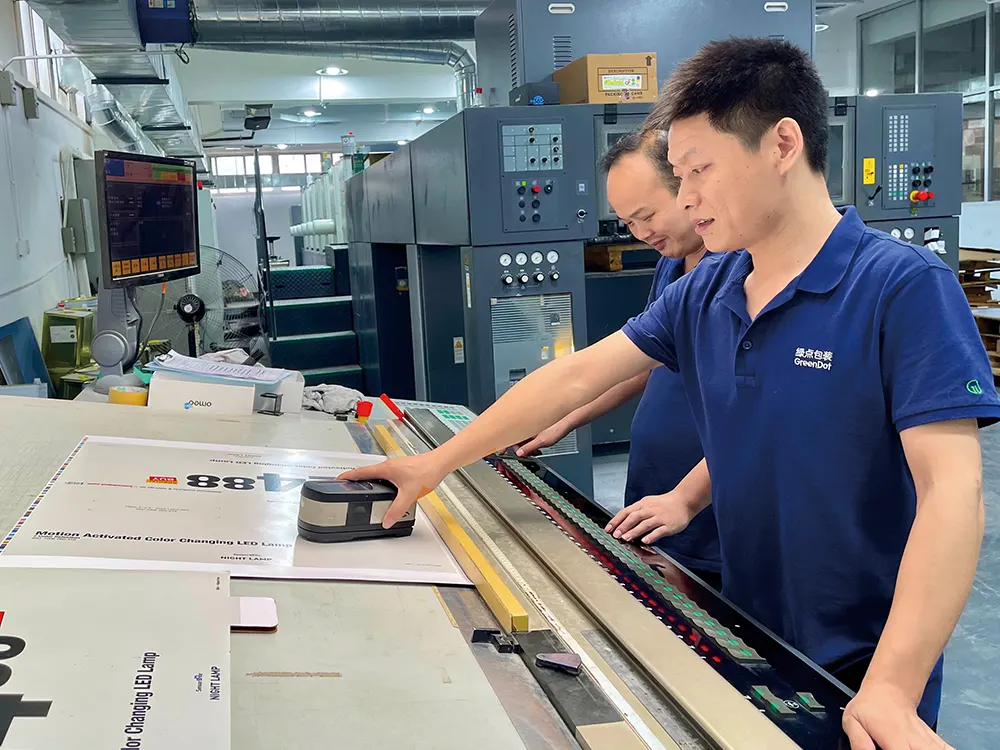

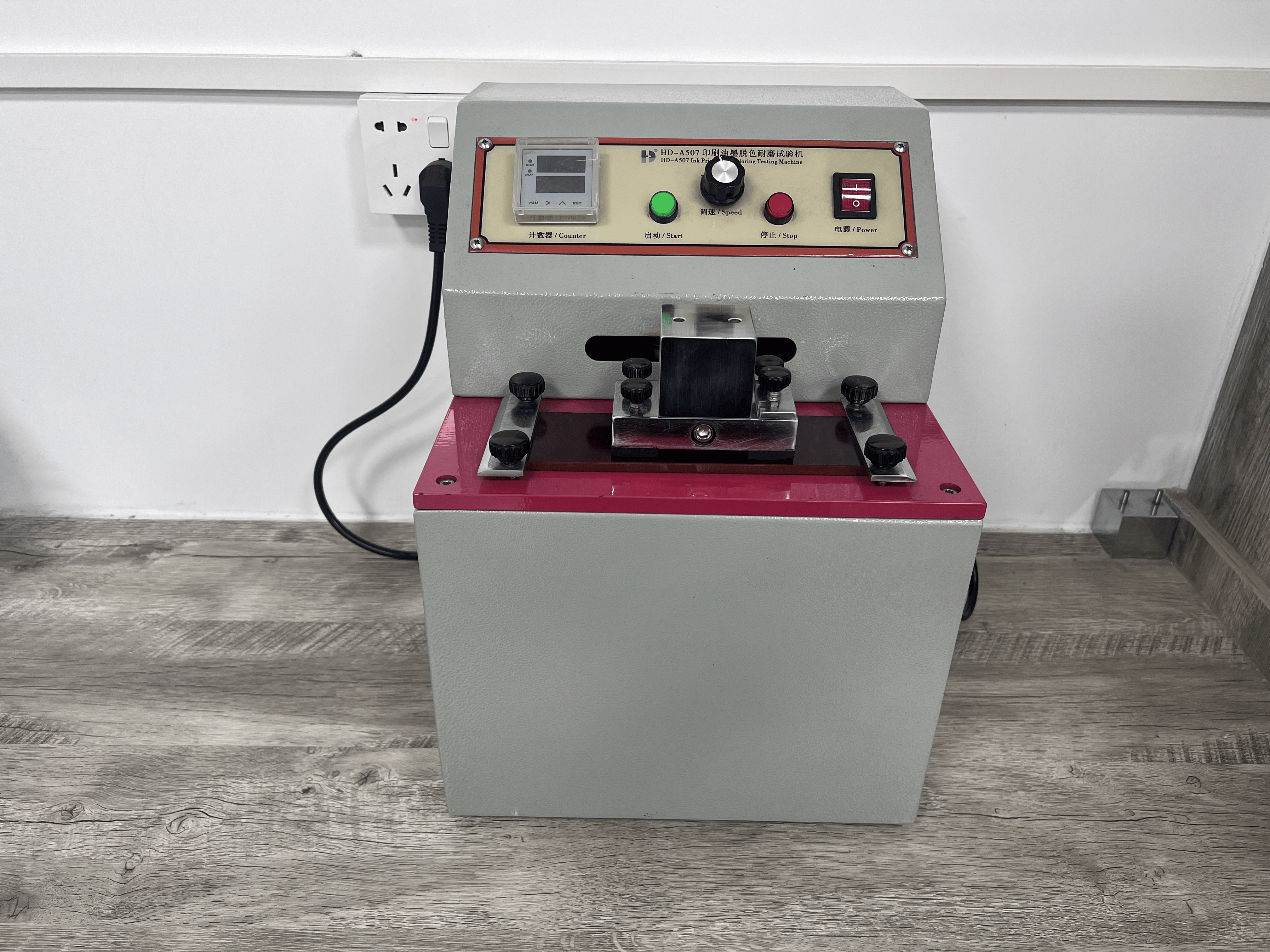

At GreenDot Packaging, color consistency isn’t just a visual standard – it’s a brand promise. We support marketing teams, printers, and suppliers with expert tools and tight controls to ensure your packaging always matches your brand’s expectations, across flexo, offset, digital, and specialty print formats.

We produce precise offset and flexographic color guides tailored to your brand’s specifications. These cards are shared with all printers, suppliers, and QA teams to standardize expectations and eliminate guesswork during production.

We provide printed color chips for each of your key packaging substrates – from corrugate to carton board to specialty materials – ensuring accurate color targeting regardless of surface.

Every color card includes standardized ink callouts to ensure seamless interpretation by printers, across both domestic and international facilities.

We tailor cards for different production regions or vendor sites, accounting for press type, ink systems, and local substrate availability.

As a designated Target Own Brand supplier, we understand the exacting color requirements that come with leading retail programs. Whether you’re managing national brands or complex private label lines, we align every packaging SKU to retailer specifications – ensuring perfect shelf presentation across print vendors, substrates, and pack formats. Our expertise includes:

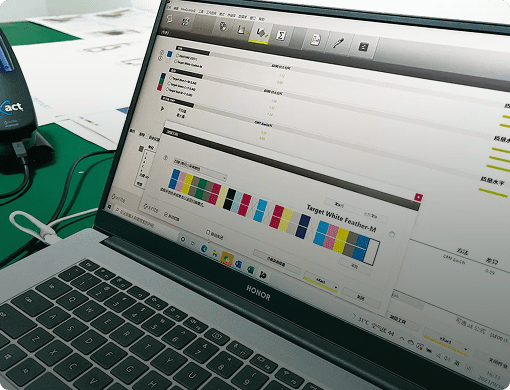

We support our clients and print partners by validating color accuracy at every critical stage – from prepress approval to full production. Whether we’re printing the job or reviewing print samples from multiple designated suppliers, our team uses calibrated tools to ensure color consistency meets your brand standards across all substrates and printers.

Our Tools & Process:

Our ISTA-certified lab enables full-spectrum testing of packaging and retail displays without the delays of third-party labs. From structural durability to transit simulation, every test is conducted on-site using calibrated equipment that meets or exceeds industry standards.

This in-house capability allows us to streamline packaging validation – reducing lead time, cutting costs, and ensuring retailer compliance.

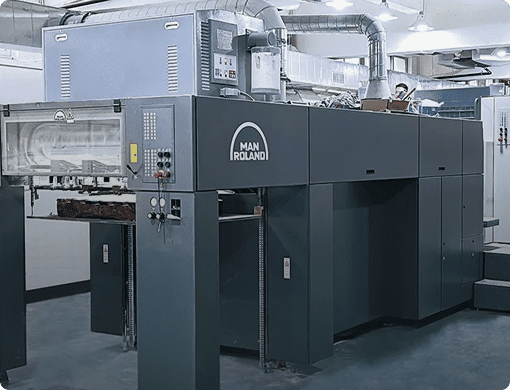

Our production floor supports a full range of printing needs – from detailed retail cartons to large-format displays. We operate both offset lithography and flexography presses, including:

KBA 162 5C (Offset) – 1620 × 1200 mm

KSL 4C Flexo – 3200 × 1600 mm

Roland 700 6C – High-resolution offset work

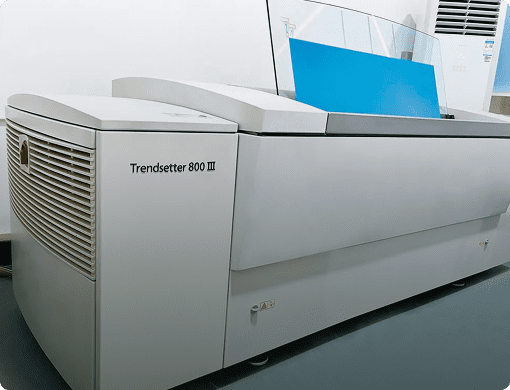

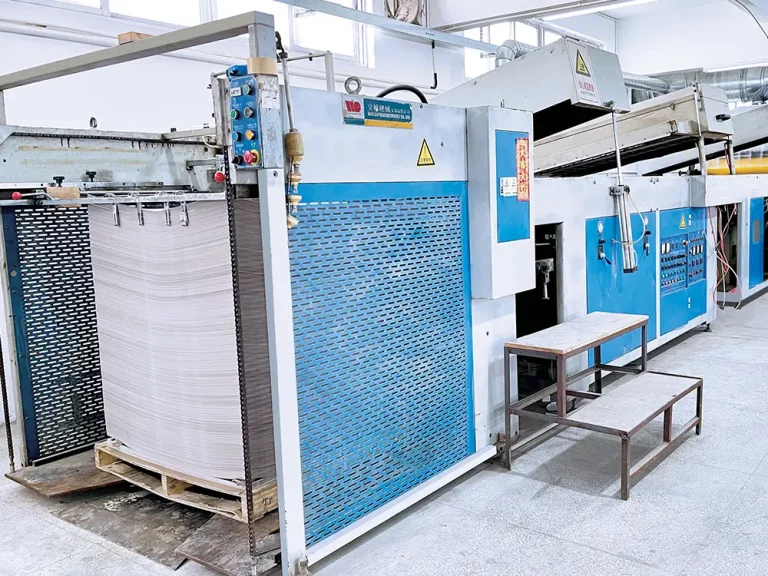

We’ve automated much of our process to reduce costs and ensure consistency, using equipment like CTP (computer-to-plate), automatic gluing, and die-cutting machines. Every job is engineered for speed, accuracy, and scalability.

Precision 6-color offset press for retail packaging and color-critical applications.

Large-format offset press (1620 × 1200 mm) for high-volume cartons and displays.

Applies matte/gloss finishes for durability and branding effect.

High-speed imaging for accurate prepress plate creation.

Handles large-format die-cutting with speed and accuracy.

Mid-format die-cutting for standard packaging.

For smaller batches or specialty jobs.

Fast, precise gluing for folding cartons and displays.

When packaging fails in transit testing, doesn’t meet retail specs, or requires too much labor to assemble – redesign becomes essential. GreenDot supports packaging improvements that go beyond surface changes. Whether you’re aiming for sustainability, cost reduction, or compliance, we engineer solutions that pass tests, reduce costs, and improve shelf readiness.

Packaging that fails drop, vibration, or compression testing can delay launch and risk damage in transit.

We support:

Reinforced structural redesigns

Optimized foam/corrugate combinations

Pre-test mockups + validation

Retailers often impose tight restrictions on packaging dimensions, facing, and pallet usage.

We ensure:

Compliance with Target / Sam’s Club / Walmart specs

Optimized shelf layout + tray fit

Packaging that passes both visual + logistical audits

Eliminate single-use foams like EPS and EPE while maintaining protective performance.

We provide:

Engineered corrugate structures

Molded pulp or fold-flat inserts

Sustainability improvements without performance loss

Packaging that’s too complex can slow fulfillment and increase cost-per-unit.

We engineer:

Glue-free and snap-lock designs

Tray + insert simplifications

Fast-assembly retail displays